The insights behind efficient aluminum casting and foundry operations

Exactly How Light Weight Aluminum Casting Adds To Reliable Manufacturing Solutions

Light weight aluminum casting plays an important duty in modern-day production. Its lightweight nature and deterioration resistance make it a favored selection for various markets. Methods such as die spreading and sand casting enable the production of detailed get rid of marginal waste. The combination of automation further boosts production efficiency. The ramifications of these developments expand beyond simple efficiency - Precision aluminum casting. Comprehending the broader impact exposes substantial insights right into the future of production

The Advantages of Light Weight Aluminum in Production

Although numerous steels are used in manufacturing, light weight aluminum stands apart due to its special buildings that boost manufacturing effectiveness and item efficiency. Its light-weight nature notably lowers transport prices and energy requirements in different applications. Aluminum's exceptional corrosion resistance assurances longevity and resilience, reducing the requirement for frequent replacements and upkeep. This metal can be conveniently built and shaped, permitting functional style options that satisfy specific sector needs. Additionally, light weight aluminum exhibits premium thermal and electrical conductivity, making it an excellent choice for applications calling for reliable heat dissipation and electric management. The recyclability of light weight aluminum likewise plays a crucial duty in sustainable production techniques, as it can be reused without shedding its fundamental buildings. On the whole, the benefits of aluminum in manufacturing result in set you back savings, improved product durability, and a minimized ecological footprint, making it a favored material in numerous sectors.

Secret Light Weight Aluminum Casting Techniques

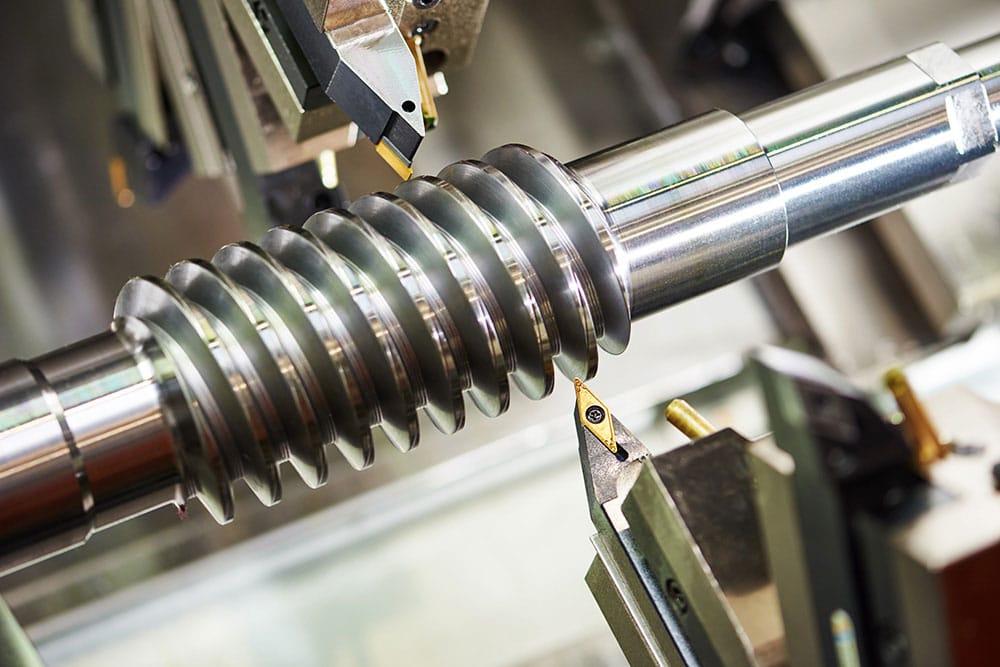

Aluminum casting techniques are vital for producing high-quality parts in numerous making procedures. The key approaches consist of sand spreading, pass away casting, and financial investment casting. Sand spreading includes producing a mold from sand, which enables big parts and complicated shapes. This strategy is commonly preferred for its cost-effectiveness and adaptability. Pass away casting, on the other hand, utilizes high-pressure to inject liquified light weight aluminum right into steel molds, resulting in precise, consistent components suitable for high-volume manufacturing. Investment spreading uses premium surface finish and complex detail by utilizing a wax pattern that is melted away to create the mold and mildew. Each of these strategies has particular applications and advantages, permitting makers to choose one of the most suitable method based upon factors like production quantity, complexity, and product specs. By understanding these crucial techniques, makers can boost their manufacturing efficiency and guarantee the stability of their aluminum components.

Influence on Automotive Sector

As the auto market significantly prioritizes lightweight products to enhance gas performance and performance, aluminum casting has become a crucial option. This manufacturing procedure enables car manufacturers to produce complicated components with lowered weight without jeopardizing structural honesty. By using light weight aluminum casting, makers can create parts such as engine blocks, transmission housings, and suspension parts that are not only lighter yet also show superb thermal conductivity and corrosion resistance.

The versatility of aluminum casting strategies allows the production of elaborate layouts, helping with technology in automobile looks and functionality. As automobiles come to be much more highly advanced, the capability to incorporate functions like advanced safety systems and electric drivetrains becomes important.

Aerospace Applications of Light Weight Aluminum Casting

Aluminum casting plays a critical function in aerospace applications by making it possible for the production of light-weight structural parts that improve gas effectiveness. In addition, the accuracy of light weight aluminum casting enables the development of intricate engine parts, which are necessary for peak efficiency and dependability. This combination of light-weight products and precise design positions aluminum spreading as a crucial innovation in the aerospace industry.

Lightweight Structural Parts

In the quest for improved efficiency and efficiency in aerospace applications, light-weight structural parts have become increasingly essential. Light weight aluminum spreading plays a pivotal role in this venture, providing producers with the capacity to generate parts that are both strong and lightweight. The low thickness of aluminum permits considerable weight decreases without compromising architectural stability, which is critical for aircraft efficiency and fuel efficiency. Additionally, aluminum spreadings can be crafted to fulfill specific style needs, making it possible for the creation of complex geometries that conventional production approaches might have a hard time to accomplish. This convenience not only improves production procedures but additionally adds to overall cost savings. As the aerospace market proceeds to highlight sustainability, the demand for lightweight light weight aluminum parts is anticipated to climb, better progressing advancement in production.

Precision Engine Components

Producers increasingly rely on light weight aluminum spreading to create precision engine components for aerospace applications, driven by the product's special buildings. Aluminum's lightweight nature significantly decreases total aircraft weight, boosting gas efficiency and performance. Its excellent deterioration resistance guarantees longevity in harsh atmospheres, making it perfect for important engine elements. Additionally, light weight aluminum spreading enables detailed styles and limited resistances, important for maximizing engine efficiency and reliability. The casting procedure likewise supports automation, making it possible for suppliers to fulfill high need while preserving high quality standards. As aerospace modern technology proceeds to advancement, the duty of aluminum spreading in developing accuracy engine components will be pivotal in achieving greater efficiency and innovation in aircraft layout and capability.

Sustainability and Environmental Benefits

The growing emphasis on sustainability in production has actually positioned aluminum spreading as a leading option for ecologically mindful manufacturing. This process utilizes recycled light weight aluminum, which considerably minimizes power intake contrasted to key light weight aluminum manufacturing. By leveraging scrap steel, makers can lower their carbon footprint and reduce waste, lining up with international sustainability objectives.

Additionally, aluminum casting produces less harmful discharges, adding to a cleaner setting. The lightweight nature of aluminum likewise improves fuel performance in transport applications, additionally promoting eco-friendly practices.

Additionally, the sturdiness and rust resistance of light weight aluminum lead to longer item lifespans, lowering the demand for frequent replacements and preserving resources. As markets significantly focus on sustainable selections, aluminum casting attracts attention as an ingenious approach that not just fulfills manufacturing needs yet likewise supports environmental stewardship. This dedication to sustainability positions aluminum spreading as an essential player in the change towards a greener production landscape.

Price Effectiveness in Production

Expense efficiency is a considerable advantage of light weight aluminum spreading, complementing its sustainability advantages - aluminum casting. The process of light weight aluminum spreading enables the production of complicated forms with marginal waste, which is especially important in an affordable manufacturing environment. Making use of aluminum lowers power expenses, look at here now as it has a lower melting point compared to various other steels, resulting in lowered power consumption during production

Additionally, light weight aluminum's light-weight properties add to decrease shipping and taking care of prices, additionally enhancing overall price performance. The longevity and rust resistance of light weight aluminum actors products likewise imply that they call for much less upkeep and substitute over time, causing long-term financial savings for manufacturers.

Innovations in casting technologies, such as enhanced mold and mildew layouts and automation, have streamlined production processes, reducing labor costs and increasing result efficiency. On the whole, price performance in aluminum casting plays a vital function in maximizing manufacturing procedures and sustaining competitive rates approaches.

Future Fads in Aluminum Casting

The future of aluminum casting is progressively shaped by Look At This advancements in automation and lasting product developments. Automation technologies are expected to boost performance and accuracy in the casting procedure, while sustainable practices intend to minimize ecological influence. Together, these fads guarantee to redefine production standards and techniques within the light weight aluminum casting industry.

Automation in Aluminum Casting

Welcoming automation is changing aluminum casting procedures, leading the way for improved efficiency and accuracy. Automated systems streamline manufacturing by reducing human treatment, decreasing mistakes, and raising throughput. Technologies such as robot arms and computer mathematical control (CNC) machines enable regular and precise shaping of light weight aluminum components. Furthermore, smart sensors keep track of numerous criteria in genuine time, ensuring suitable conditions throughout the spreading process. This integration of automation not just reduces lead times yet likewise enhances item top quality by maintaining tighter resistances. As manufacturers increasingly adopt these sophisticated modern technologies, the aluminum casting industry is set to experience substantial enhancements in operational effectiveness, cost-effectiveness, and competition in the international market.

Sustainable Material Innovations

Regularly Asked Questions

What Kinds of Light Weight Aluminum Alloys Are Frequently Utilized in Casting?

Commonly utilized light weight aluminum alloys in casting include 356, 380, and 413. These alloys are favored for their superb fluidity, strength, and rust resistance, making them suitable for a selection of commercial applications.

Exactly How Does Light Weight Aluminum Casting Contrast to Various Other Steel Casting Techniques?

Aluminum casting generally offers lower weight, superior corrosion resistance, and better thermal conductivity contrasted to other metal spreading approaches. In addition, it enables complex styles and faster manufacturing cycles, boosting total production performance and efficiency.

What Industries Benefit The Majority Of From Aluminum Spreading?

The automotive, aerospace, and electronic devices markets profit most from aluminum spreading. These industries utilize its lightweight, corrosion-resistant properties to boost performance, decrease gas usage, and boost general item performance, making aluminum spreading progressively crucial.

Are There Details Style Limitations With Light Weight Aluminum Spreading?

Yes, aluminum spreading has design limitations, consisting of constraints on wall thickness, facility geometry challenges, and prospective concerns with accomplishing limited resistances (Aluminum Casting Company). These variables can influence the general strength and performance of the last product

Just How Is Top Quality Control Maintained in Aluminum Spreading Processes?

Quality control in aluminum spreading processes is maintained through strenuous evaluations, adherence to standardized procedures, and using sophisticated innovations. Normal tracking guarantees dimensional accuracy, surface area honesty, and material consistency throughout production, promoting overall integrity.

As the automobile market progressively focuses on light-weight materials to boost gas performance and performance, aluminum spreading has actually arised as a crucial option. Aluminum spreading plays an essential role in aerospace applications by making it possible for the production of lightweight architectural components that boost fuel effectiveness. Cost performance is a significant advantage of aluminum casting, complementing its sustainability benefits. Welcoming automation is changing light weight aluminum spreading procedures, leading the method for enhanced efficiency and precision. Recycled light weight aluminum usage has actually gotten traction, substantially reducing energy usage contrasted to key aluminum manufacturing.